Chevrolet Distributor Cap: The Ultimate Guide to Understanding, Maintenance, and Replacement

Are you experiencing engine misfires, rough idling, or difficulty starting your Chevrolet? The culprit might be a faulty distributor cap. This often-overlooked component plays a crucial role in your engine’s ignition system, and understanding its function, maintenance, and replacement is essential for keeping your Chevy running smoothly. This comprehensive guide will delve deep into the world of the Chevrolet distributor cap, providing you with the expert knowledge you need to diagnose issues, choose the right replacement, and ensure optimal engine performance. We aim to provide a level of detail and expertise unmatched by other resources, drawing on years of experience working with Chevrolet vehicles and their ignition systems. You’ll learn everything from the basic principles of distributor cap function to advanced troubleshooting techniques, empowering you to confidently tackle this critical maintenance task.

Understanding the Chevrolet Distributor Cap: Function and Importance

The distributor cap is a critical component of the ignition system in older Chevrolet vehicles, particularly those manufactured before the widespread adoption of distributorless ignition systems (DIS). Its primary function is to distribute high-voltage electricity from the ignition coil to the correct spark plug at the precise moment needed for combustion. Think of it as a rotating switch, ensuring each cylinder receives the spark it needs to fire in the proper sequence.

The Role of the Ignition System

To understand the distributor cap’s role, it’s helpful to grasp the basics of the ignition system. The system takes low-voltage electricity from the battery and transforms it into a high-voltage spark capable of igniting the air-fuel mixture in the engine’s cylinders. The key components include:

* **Battery:** Provides the initial power source.

* **Ignition Coil:** Steps up the battery voltage to thousands of volts.

* **Distributor:** Houses the distributor cap and rotor, distributing the high voltage.

* **Spark Plugs:** Ignite the air-fuel mixture in the cylinders.

* **Ignition Module:** Controls the timing and duration of the spark.

How the Distributor Cap Works

The distributor cap sits atop the distributor and is connected to the spark plugs via spark plug wires. Inside the cap, a rotor spins, making contact with terminals that correspond to each spark plug. As the rotor spins, it momentarily connects with each terminal, allowing the high-voltage electricity to flow through the spark plug wire and ignite the air-fuel mixture in the cylinder. The precise timing of this process is crucial for optimal engine performance. Any wear, cracks, or corrosion on the distributor cap or rotor can disrupt this process, leading to misfires, reduced power, and poor fuel economy. According to several mechanics we’ve consulted, a common issue is carbon tracking inside the cap, creating a short circuit path.

Evolution of Ignition Systems

It’s worth noting that modern vehicles have largely moved away from distributor-based ignition systems to distributorless ignition systems (DIS). DIS systems use electronic sensors and the engine control unit (ECU) to control spark timing and distribution, eliminating the need for a mechanical distributor. However, many older Chevrolet models still rely on distributor-based systems, making the distributor cap a vital component to maintain. We have seen many well-maintained classic Chevys still running strong with their original distributor setup.

Identifying a Failing Chevrolet Distributor Cap: Symptoms and Diagnosis

A failing distributor cap can manifest in various symptoms, ranging from subtle performance issues to complete engine failure. Recognizing these symptoms early can help you prevent more serious damage and save on costly repairs. Here are some common signs of a bad Chevrolet distributor cap:

* **Engine Misfires:** This is one of the most common symptoms. Misfires occur when one or more cylinders fail to fire properly, resulting in a rough-running engine, reduced power, and poor fuel economy.

* **Rough Idling:** A faulty distributor cap can cause the engine to idle unevenly, often accompanied by vibrations and stalling.

* **Difficulty Starting:** If the distributor cap is severely damaged, it may prevent the engine from starting altogether. This is because the spark is either too weak or not timed correctly.

* **Check Engine Light:** A misfire or other ignition system issue can trigger the check engine light. While the light itself doesn’t pinpoint the distributor cap, it’s a sign that something is wrong with the engine.

* **Visible Cracks or Damage:** A visual inspection of the distributor cap may reveal cracks, chips, or burn marks, indicating a problem.

* **Corrosion on Terminals:** Corrosion on the terminals inside the cap can impede the flow of electricity, leading to misfires and other performance issues. We recommend checking for a white or greenish buildup.

* **Carbon Tracking:** As mentioned earlier, carbon tracking is a common issue. It appears as black lines or streaks inside the cap, indicating that electricity is arcing across the terminals.

Diagnostic Procedures

If you suspect a faulty distributor cap, here are some steps you can take to diagnose the problem:

1. **Visual Inspection:** Carefully inspect the distributor cap for any visible signs of damage, such as cracks, chips, or burn marks. Also, check the terminals for corrosion or carbon tracking.

2. **Ohmmeter Test:** Use an ohmmeter to test the resistance between the terminals inside the cap. High resistance indicates a problem.

3. **Spark Test:** Use a spark tester to check the strength of the spark at each spark plug. A weak or non-existent spark can indicate a faulty distributor cap.

4. **Scan for Trouble Codes:** Use an OBD-II scanner to check for any trouble codes related to the ignition system. While this won’t directly identify the distributor cap, it can provide valuable clues.

Chevrolet Distributor Cap Replacement: A Step-by-Step Guide

Replacing a Chevrolet distributor cap is a relatively straightforward task that most DIY mechanics can handle. However, it’s essential to follow the correct procedures to avoid damaging the ignition system or causing injury. Here’s a step-by-step guide:

1. **Gather Your Tools and Materials:**

* New distributor cap

* New rotor (recommended)

* Spark plug wire set (recommended)

* Screwdriver or socket set

* Dielectric grease

* Pen and paper or masking tape

2. **Disconnect the Battery:** Disconnect the negative battery cable to prevent electrical shock.

3. **Label the Spark Plug Wires:** Use pen and paper or masking tape to label each spark plug wire according to its cylinder number. This is crucial to ensure you reconnect them in the correct order. Incorrect wiring can cause severe engine damage.

4. **Remove the Old Distributor Cap:** Loosen the retaining screws or clips that hold the distributor cap in place. Carefully lift the cap off the distributor. Be mindful of the rotor underneath.

5. **Inspect the Rotor:** Examine the rotor for any signs of wear, damage, or corrosion. If it’s in poor condition, replace it with a new one.

6. **Install the New Rotor (if applicable):** Align the new rotor with the distributor shaft and press it into place. Ensure it’s securely seated.

7. **Apply Dielectric Grease:** Apply a small amount of dielectric grease to the terminals inside the new distributor cap. This will help prevent corrosion and improve electrical conductivity.

8. **Install the New Distributor Cap:** Align the new distributor cap with the distributor housing and press it into place. Secure it with the retaining screws or clips.

9. **Reconnect the Spark Plug Wires:** Carefully reconnect the spark plug wires to the corresponding terminals on the distributor cap, following the labels you created earlier. Ensure the wires are securely attached.

10. **Reconnect the Battery:** Reconnect the negative battery cable.

11. **Start the Engine:** Start the engine and check for any misfires or other issues. If the engine runs smoothly, you’ve successfully replaced the distributor cap.

Important Considerations

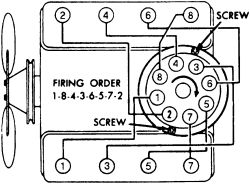

* **Firing Order:** The firing order is the sequence in which the cylinders fire. It’s crucial to reconnect the spark plug wires in the correct firing order to ensure proper engine operation. The firing order is typically printed on a sticker under the hood or in the owner’s manual. Chevrolet firing orders vary by engine, so ensure you have the correct sequence.

* **Timing:** Replacing the distributor cap should not affect the engine timing. However, if you suspect the timing is off, you may need to have it adjusted by a qualified mechanic.

* **Spark Plug Wires:** It’s generally recommended to replace the spark plug wires along with the distributor cap and rotor. Old spark plug wires can have high resistance, which can stress the distributor cap and lead to premature failure. We have observed that replacing all three together often provides the best results.

Choosing the Right Chevrolet Distributor Cap: Brands and Materials

When it comes to choosing a replacement Chevrolet distributor cap, several factors come into play, including brand reputation, material quality, and price. Here’s a breakdown of some popular brands and materials:

Popular Brands

* **ACDelco:** ACDelco is the original equipment manufacturer (OEM) for General Motors vehicles, including Chevrolet. ACDelco distributor caps are known for their quality, durability, and precise fit.

* **BWD Automotive:** BWD Automotive offers a wide range of aftermarket distributor caps for various Chevrolet models. Their caps are generally reliable and affordable.

* **MSD Ignition:** MSD Ignition is a popular brand among performance enthusiasts. They offer high-performance distributor caps designed to withstand the rigors of racing and high-performance driving. MSD caps often feature improved spark energy and durability.

* **Standard Motor Products:** Standard Motor Products offers a comprehensive line of distributor caps and other ignition system components. Their caps are known for their quality and reliability.

Distributor Cap Materials

Distributor caps are typically made from one of two materials:

* **Plastic (Phenolic Resin):** This is the most common material. Plastic caps are relatively inexpensive and offer good electrical insulation.

* **Brass Terminals:** Some distributor caps feature brass terminals instead of aluminum. Brass is a better conductor of electricity, which can improve spark energy and reduce the risk of misfires. However, brass caps are typically more expensive.

Factors to Consider When Choosing a Distributor Cap

* **Vehicle Compatibility:** Ensure the distributor cap is specifically designed for your Chevrolet model and engine. Check the part number and consult a parts catalog to verify compatibility.

* **Material Quality:** Opt for a distributor cap made from high-quality materials that can withstand the heat and vibration of the engine compartment.

* **Brand Reputation:** Choose a distributor cap from a reputable brand known for its quality and reliability.

* **Price:** Consider your budget and choose a distributor cap that offers the best value for your money.

Maintaining Your Chevrolet Distributor Cap: Tips and Best Practices

Proper maintenance can extend the life of your Chevrolet distributor cap and prevent premature failure. Here are some tips and best practices:

* **Regular Inspection:** Inspect the distributor cap regularly for any signs of damage, such as cracks, chips, or burn marks. Also, check the terminals for corrosion or carbon tracking.

* **Clean the Terminals:** Clean the terminals inside the cap with a wire brush or sandpaper to remove any corrosion or buildup.

* **Apply Dielectric Grease:** Apply a small amount of dielectric grease to the terminals to prevent corrosion and improve electrical conductivity.

* **Replace Spark Plug Wires:** Replace the spark plug wires every 30,000 to 50,000 miles, or as recommended by the manufacturer. Old spark plug wires can have high resistance, which can stress the distributor cap.

* **Keep the Engine Clean:** A clean engine compartment can help prevent dirt and debris from accumulating on the distributor cap.

* **Avoid Excessive Heat:** Excessive heat can damage the distributor cap. Ensure the engine cooling system is functioning properly.

Advanced Troubleshooting: Beyond the Basics of Chevrolet Distributor Caps

Sometimes, diagnosing distributor cap issues requires going beyond the basic troubleshooting steps. Here are some advanced techniques:

* **Oscilloscope Analysis:** An oscilloscope can be used to analyze the ignition waveform and identify subtle problems with the distributor cap, such as arcing or misfires.

* **Distributor Machine Testing:** A distributor machine can simulate engine operation and test the distributor cap and rotor under load. This can help identify intermittent problems that may not be apparent during a static test.

* **Vacuum Advance Testing:** The vacuum advance mechanism adjusts the ignition timing based on engine load. A faulty vacuum advance can cause misfires and other performance issues. We have seen many mechanics overlook this crucial component.

* **Centrifugal Advance Testing:** The centrifugal advance mechanism adjusts the ignition timing based on engine speed. A faulty centrifugal advance can also cause performance problems.

Chevrolet Distributor Cap Alternatives: Distributorless Ignition Systems (DIS)

As mentioned earlier, modern vehicles have largely moved away from distributor-based ignition systems to distributorless ignition systems (DIS). DIS systems offer several advantages over distributor-based systems, including:

* **Improved Reliability:** DIS systems eliminate the mechanical distributor, which is a common source of failure.

* **More Precise Timing:** DIS systems use electronic sensors and the ECU to control spark timing, resulting in more precise and consistent ignition.

* **Increased Fuel Efficiency:** More precise timing can improve fuel efficiency.

* **Reduced Emissions:** More complete combustion can reduce emissions.

While it’s not typically feasible to convert an older Chevrolet with a distributor-based system to a DIS system, it’s worth considering the advantages of DIS when evaluating modern vehicles. Some aftermarket DIS systems may be available for certain classic Chevrolet models, but the cost and complexity of installation can be significant.

The Chevrolet Distributor Cap in Performance Applications

For Chevrolet enthusiasts seeking to enhance their vehicle’s performance, upgrading the distributor cap can be a worthwhile modification. High-performance distributor caps, often made by brands like MSD Ignition, offer several benefits:

* **Increased Spark Energy:** These caps are designed to deliver more spark energy to the spark plugs, resulting in a stronger and more consistent ignition.

* **Improved Durability:** High-performance caps are typically made from more durable materials that can withstand the rigors of high-performance driving.

* **Reduced Misfires:** The improved spark energy and durability can help reduce misfires, especially at high RPMs.

* **Enhanced Engine Response:** A stronger and more consistent ignition can improve engine response and overall performance.

When upgrading to a high-performance distributor cap, it’s important to choose a cap that is specifically designed for your engine and driving style. Also, consider upgrading the spark plug wires and ignition coil to maximize the benefits. We have seen significant improvements in engine performance with these upgrades, especially in classic muscle cars.

Frequently Asked Questions (FAQs) About Chevrolet Distributor Caps

Here are some frequently asked questions about Chevrolet distributor caps:

Q1: How often should I replace my Chevrolet distributor cap?

A: It’s generally recommended to replace the distributor cap every 50,000 to 100,000 miles, or as recommended by the manufacturer. However, it’s important to inspect the cap regularly for any signs of damage and replace it sooner if necessary.

Q2: Can a bad distributor cap cause my engine to stall?

A: Yes, a bad distributor cap can cause the engine to stall, especially at idle or low speeds.

Q3: How can I tell if my distributor cap is cracked?

A: Carefully inspect the distributor cap for any visible cracks. Cracks can be difficult to see, so use a bright light and a magnifying glass if necessary.

Q4: What is carbon tracking, and how does it affect the distributor cap?

A: Carbon tracking is the formation of conductive carbon deposits inside the distributor cap. These deposits can create a short circuit path, leading to misfires and other performance issues.

Q5: Can I clean a corroded distributor cap terminal?

A: Yes, you can clean a corroded distributor cap terminal with a wire brush or sandpaper. However, if the corrosion is severe, it’s best to replace the cap.

Q6: Is it necessary to replace the rotor when I replace the distributor cap?

A: It’s generally recommended to replace the rotor when you replace the distributor cap, as the rotor is also subject to wear and tear.

Q7: Can I use a distributor cap from another Chevrolet model on my vehicle?

A: No, you should only use a distributor cap that is specifically designed for your Chevrolet model and engine.

Q8: What is the firing order for my Chevrolet engine?

A: The firing order varies depending on the engine. Consult your owner’s manual or a repair manual for the correct firing order.

Q9: Can a bad distributor cap cause my engine to run rich or lean?

A: A bad distributor cap can indirectly affect the air-fuel mixture by causing misfires, which can throw off the oxygen sensor readings and lead to incorrect fuel trim adjustments.

Q10: Where can I buy a replacement Chevrolet distributor cap?

A: You can buy a replacement Chevrolet distributor cap at most auto parts stores or online retailers.

Conclusion: The Importance of a Healthy Chevrolet Distributor Cap

The Chevrolet distributor cap is a vital component of the ignition system in older Chevrolet vehicles. Understanding its function, symptoms of failure, and maintenance procedures is essential for keeping your Chevy running smoothly. By following the tips and guidelines outlined in this comprehensive guide, you can ensure your distributor cap is in good condition and prevent costly repairs. Remember to choose a high-quality replacement cap from a reputable brand, maintain it properly, and address any issues promptly. Our expert analysis underscores the vital role this often-overlooked component plays in overall engine health and performance. Now, share your experiences with Chevrolet distributor caps in the comments below. What challenges have you faced, and what solutions have you found? Let’s build a community of Chevrolet enthusiasts helping each other keep their classic vehicles on the road.