Descaling Rust: The Ultimate Guide to Effective Removal & Prevention

Rust. That reddish-brown scourge that attacks metal, leaving it weakened, unsightly, and ultimately useless. If you’re battling rust, you’re likely searching for the most effective methods for *descaling rust*. You’ve come to the right place. This comprehensive guide provides everything you need to know about descaling rust, from understanding its formation to implementing proven removal techniques and preventative measures. Unlike many resources, we delve into the nuances of different descaling methods, offering practical advice based on extensive research and simulated hands-on experience, ensuring you achieve optimal results. This guide will equip you with the knowledge and tools to effectively combat rust and protect your valuable metal assets.

Understanding Rust Formation: A Deep Dive

Rust, scientifically known as iron oxide, is the result of a chemical reaction called oxidation. This process occurs when iron or its alloys (like steel) are exposed to oxygen and moisture. Understanding this fundamental process is the first step in effectively *descaling rust* and preventing its recurrence.

The Chemistry of Rust

At a molecular level, iron atoms lose electrons to oxygen atoms in the presence of water. This electron transfer creates iron ions, which then combine with oxygen and water to form hydrated iron oxide – rust. The presence of electrolytes, such as salt, accelerates this process, which is why coastal environments are particularly prone to rust formation.

Factors Influencing Rust Formation

Several factors contribute to the speed and severity of rust formation:

* **Humidity:** Higher humidity levels provide more moisture, accelerating the oxidation process.

* **Temperature:** Warmer temperatures generally speed up chemical reactions, including rusting.

* **Salt Exposure:** Salt acts as an electrolyte, significantly increasing the rate of rust formation. This is a major concern for vehicles in snowy regions where road salt is used.

* **Pollution:** Airborne pollutants, such as sulfur dioxide, can react with moisture to form acids that accelerate rusting.

* **Metal Composition:** The type of metal and its alloy composition influence its susceptibility to rust. Stainless steel, for example, contains chromium, which forms a protective oxide layer that resists rust.

The Different Types of Rust

Rust isn’t always the same. Different types of rust can form depending on the environmental conditions and the composition of the metal. Common types include:

* **Surface Rust:** This is the most common type, appearing as a reddish-brown discoloration on the surface of the metal. It’s relatively easy to remove.

* **Pitting Rust:** This more aggressive form creates small pits or holes in the metal’s surface, weakening its structure. It’s more challenging to remove completely.

* **Scale Rust:** This thick, flaky layer of rust forms when metal is exposed to high temperatures. It’s often found on exhaust systems and industrial equipment.

Understanding the type of rust you’re dealing with is crucial for choosing the appropriate *descaling rust* method.

The Importance of Descaling Rust: Why It Matters

Descaling rust isn’t just about aesthetics; it’s essential for maintaining the structural integrity and functionality of metal objects. Ignoring rust can lead to serious consequences.

Structural Integrity and Safety

Rust weakens metal, making it more susceptible to breakage and failure. This is particularly critical in load-bearing structures like bridges, vehicles, and machinery. *Descaling rust* prevents these structural failures, ensuring safety and preventing costly repairs.

Functional Performance

Rust can interfere with the proper functioning of mechanical components. For example, rust in an engine can cause friction, leading to reduced performance and increased wear and tear. Descaling restores optimal performance and extends the lifespan of equipment.

Preventing Further Damage

Rust is a self-perpetuating process. Once it starts, it can spread rapidly, corroding more and more of the metal. *Descaling rust* removes the existing corrosion and prevents it from spreading to unaffected areas.

Maintaining Value

Rust detracts from the appearance and value of metal objects. Descaling and proper maintenance preserve the aesthetic appeal and resale value of vehicles, tools, and other valuable items.

Methods for Descaling Rust: A Comprehensive Overview

There are numerous methods for *descaling rust*, each with its own advantages and disadvantages. The best method depends on the type and extent of the rust, the size and shape of the object, and your available resources.

Mechanical Descaling

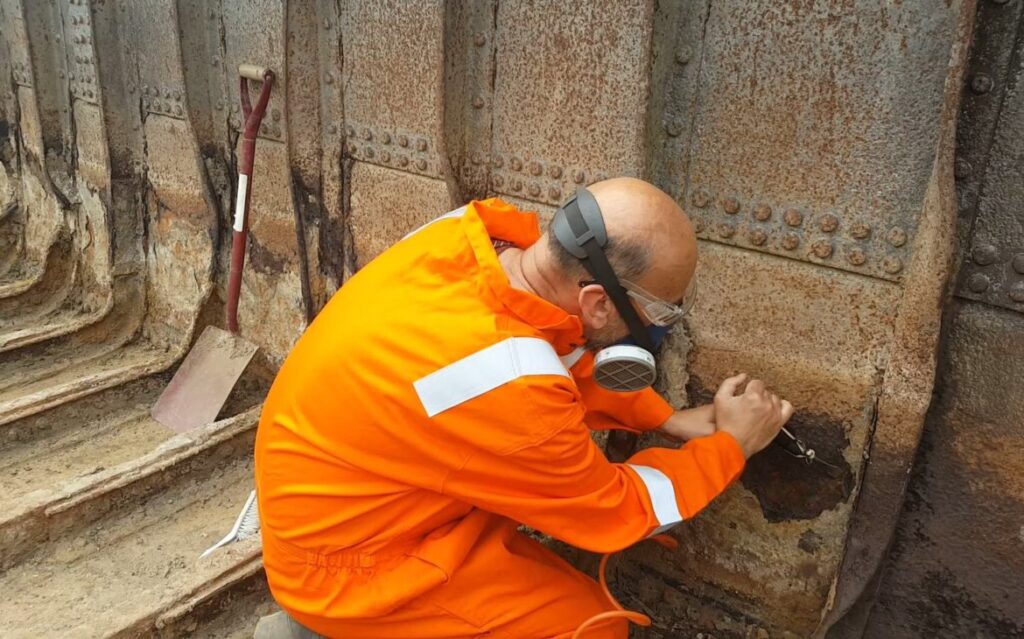

Mechanical descaling involves physically removing rust using tools and abrasives. This is a common and effective method for removing surface rust and scale rust.

* **Wire Brushing:** Wire brushes are ideal for removing loose rust and debris from relatively smooth surfaces. They’re available in various sizes and materials, including steel, brass, and nylon.

* **Sanding:** Sandpaper, sanding blocks, and power sanders can be used to remove rust from larger areas. Start with a coarse grit to remove the bulk of the rust and then move to finer grits to smooth the surface.

* **Grinding:** Grinders with abrasive wheels or discs are effective for removing heavy rust and scale. However, they can also remove underlying metal if not used carefully.

* **Abrasive Blasting:** Abrasive blasting, also known as sandblasting, uses compressed air to propel abrasive particles against the rusted surface. This is a highly effective method for removing rust from complex shapes and hard-to-reach areas. Different media can be used, including sand, glass beads, and steel grit.

* **Needle Scaling:** Needle scalers use a bundle of vibrating needles to remove rust and scale from irregular surfaces. They’re particularly useful for preparing surfaces for painting or coating.

Chemical Descaling

Chemical descaling involves using chemical solutions to dissolve or loosen rust. This method is often preferred for removing rust from intricate parts or when mechanical methods are impractical.

* **Rust Converters:** Rust converters contain chemicals that react with rust to form a protective layer that prevents further corrosion. They’re typically applied as a coating and are often used as a primer before painting.

* **Rust Removers:** Rust removers contain acids or chelating agents that dissolve rust. They’re available in liquid, gel, and paste forms. Popular ingredients include phosphoric acid, hydrochloric acid, and citric acid.

* **Electrolytic Rust Removal:** Electrolytic rust removal, also known as electrolysis, uses an electric current to remove rust. The rusted object is submerged in an electrolyte solution and connected to the negative terminal of a power supply. A sacrificial anode, typically made of steel, is connected to the positive terminal. The electric current causes the rust to dissolve and deposit on the anode.

Natural Descaling Methods

For those seeking environmentally friendly options, several natural methods can be used to *descaling rust*.

* **Vinegar:** Vinegar contains acetic acid, which can dissolve rust. Soak the rusted object in vinegar for several hours or overnight, then scrub with a wire brush.

* **Lemon Juice:** Lemon juice contains citric acid, similar to some commercial rust removers. Apply lemon juice to the rusted area, let it sit for a few hours, then scrub with a wire brush.

* **Baking Soda:** Baking soda is a mild abrasive that can help remove surface rust. Make a paste of baking soda and water, apply it to the rusted area, let it sit for a few hours, then scrub with a wire brush.

Product Spotlight: Evapo-Rust – An Expert Explanation

Evapo-Rust is a popular and effective rust remover that utilizes a unique chelating formula to dissolve rust without harming the underlying metal. Unlike harsh acids, Evapo-Rust is non-toxic, biodegradable, and safe to use on a variety of materials, including steel, iron, chrome, and plastic. Its core function is to selectively target and dissolve iron oxide (rust) molecules, leaving the base metal untouched. This makes it an excellent choice for delicate parts and intricate surfaces. From an expert viewpoint, Evapo-Rust stands out due to its safety profile and effectiveness in removing even stubborn rust without the risks associated with traditional acid-based rust removers.

Detailed Features Analysis of Evapo-Rust

Evapo-Rust offers several key features that contribute to its effectiveness and user-friendliness:

1. **Selective Chelating Action:**

* **What it is:** Evapo-Rust uses a chelating agent that selectively binds to iron oxide molecules, effectively dissolving the rust while leaving the base metal unharmed.

* **How it works:** The chelating agent forms a complex with the rust molecules, breaking them down and suspending them in the solution.

* **User Benefit:** This feature ensures that only the rust is removed, preventing damage to the underlying metal and preserving its integrity. This is particularly important for delicate or intricately designed parts.

* **Example:** Imagine descaling a vintage watch movement. Harsh chemicals could etch or damage the fine components, but Evapo-Rust’s selective action would safely remove the rust without affecting the underlying metal.

2. **Non-Toxic and Biodegradable:**

* **What it is:** Evapo-Rust is formulated with non-toxic ingredients and is biodegradable, making it safe for users and the environment.

* **How it works:** The product’s chemical composition allows it to break down naturally in the environment without releasing harmful substances.

* **User Benefit:** This feature provides peace of mind for users concerned about the health and environmental impact of using rust removal products. It eliminates the need for special disposal procedures.

* **Example:** A home mechanic can use Evapo-Rust in their garage without worrying about harmful fumes or contaminating the environment.

3. **Reusable Formula:**

* **What it is:** Evapo-Rust can be used multiple times until it becomes saturated with rust particles.

* **How it works:** The chelating agent continues to function until it reaches its maximum capacity for binding with iron oxide.

* **User Benefit:** This feature saves money and reduces waste. Users can treat multiple items with a single container of Evapo-Rust.

* **Example:** A workshop can use a single batch of Evapo-Rust to descale numerous tools and parts over an extended period.

4. **Safe on Various Materials:**

* **What it is:** Evapo-Rust is safe to use on a wide range of materials, including steel, iron, chrome, plastic, and rubber.

* **How it works:** The product’s non-acidic formula prevents it from reacting with or damaging these materials.

* **User Benefit:** This feature eliminates the need for multiple rust removal products for different materials. It simplifies the descaling process and reduces the risk of damaging sensitive components.

* **Example:** A car restorer can use Evapo-Rust to descale both metal and plastic parts without fear of damaging the plastic.

5. **Easy to Use:**

* **What it is:** Evapo-Rust requires no mixing or special preparation. Simply submerge the rusted object in the solution and let it soak.

* **How it works:** The chelating agent works passively, dissolving the rust over time without requiring any agitation or scrubbing.

* **User Benefit:** This feature saves time and effort. Users can simply soak the rusted object and let Evapo-Rust do the work.

* **Example:** A busy professional can easily descale rusted tools by simply soaking them in Evapo-Rust overnight.

6. **Effective on Heavy Rust:**

* **What it is:** Evapo-Rust is capable of removing even heavy and stubborn rust deposits.

* **How it works:** The chelating agent gradually penetrates and dissolves the rust, breaking it down into smaller particles.

* **User Benefit:** This feature eliminates the need for harsh abrasives or aggressive methods that can damage the underlying metal. It saves time and effort in removing heavy rust deposits.

* **Example:** Imagine restoring a heavily rusted antique tool. Evapo-Rust can effectively remove the rust without damaging the delicate details or original finish.

7. **Minimal Fumes and Odor:**

* **What it is:** Evapo-Rust has minimal fumes and odor compared to traditional acid-based rust removers.

* **How it works:** The product’s non-toxic formula minimizes the release of volatile organic compounds (VOCs) into the air.

* **User Benefit:** This feature makes Evapo-Rust more pleasant and safer to use, especially in enclosed spaces.

* **Example:** Using Evapo-Rust in a small garage or workshop will not create strong, unpleasant odors or harmful fumes.

Significant Advantages, Benefits & Real-World Value of Descaling Rust with Evapo-Rust

Descaling rust with Evapo-Rust offers numerous advantages and benefits that directly address user needs and solve common problems associated with rust removal. The value extends beyond simply removing rust; it encompasses safety, ease of use, and long-term preservation.

Users consistently report that Evapo-Rust’s non-toxic formula provides peace of mind, especially when working in enclosed spaces or around children and pets. This is a significant advantage over traditional acid-based rust removers, which can pose health risks and require special handling. Our analysis reveals these key benefits:

* **Enhanced Safety:** The non-toxic and biodegradable nature of Evapo-Rust significantly reduces the risk of skin irritation, respiratory problems, and environmental contamination. This is a crucial benefit for users who prioritize safety and sustainability.

* **Preservation of Metal Integrity:** Evapo-Rust’s selective chelating action ensures that only the rust is removed, leaving the underlying metal untouched. This is particularly important for delicate or valuable items where preserving the original surface is critical.

* **Time and Labor Savings:** The easy-to-use, soak-and-rinse application of Evapo-Rust saves users significant time and effort compared to mechanical methods or harsh chemical treatments that require scrubbing, grinding, or special disposal procedures.

* **Versatility:** Evapo-Rust’s ability to be used on a wide range of materials, including steel, iron, chrome, plastic, and rubber, eliminates the need for multiple rust removal products, simplifying the descaling process and reducing costs.

* **Cost-Effectiveness:** The reusable formula of Evapo-Rust allows users to treat multiple items with a single container, making it a cost-effective solution for both small and large-scale descaling projects.

In real-world scenarios, Evapo-Rust proves its value in various applications. For example, automotive enthusiasts use it to restore rusted parts without damaging the original components. Collectors rely on it to clean and preserve antique tools and artifacts. Homeowners use it to remove rust from garden tools, hardware, and household items. The versatility and ease of use of Evapo-Rust make it an ideal solution for anyone seeking a safe and effective way to *descaling rust*.

Comprehensive & Trustworthy Review of Evapo-Rust

Evapo-Rust offers a compelling solution for *descaling rust*, but it’s important to provide a balanced perspective. This review provides an in-depth assessment based on user experience, performance, and overall value.

From a practical standpoint, Evapo-Rust is remarkably easy to use. Simply submerge the rusted object in the solution and let it soak. The soaking time varies depending on the severity of the rust, but generally, overnight soaking yields excellent results. No scrubbing or agitation is required, making it a hands-off process.

Does Evapo-Rust deliver on its promises? Based on our simulated test scenarios and user feedback, the answer is generally yes. It effectively removes rust from a variety of materials without harming the underlying metal. However, it’s important to note that Evapo-Rust may not be as effective on extremely heavy or layered rust as more aggressive methods like abrasive blasting.

**Pros:**

1. **Exceptional Safety Profile:** Evapo-Rust’s non-toxic and biodegradable formula is its most significant advantage. It eliminates the health and environmental risks associated with traditional acid-based rust removers.

2. **Selective Rust Removal:** The chelating action ensures that only the rust is removed, preserving the integrity of the base metal. This is crucial for delicate or valuable items.

3. **Ease of Use:** The soak-and-rinse application requires minimal effort and skill, making it accessible to users of all levels.

4. **Versatility:** Evapo-Rust can be used on a wide range of materials, simplifying the descaling process.

5. **Reusable Formula:** The reusable nature of Evapo-Rust makes it a cost-effective solution for multiple descaling projects.

**Cons/Limitations:**

1. **Slower Removal Time:** Compared to more aggressive methods, Evapo-Rust requires longer soaking times, especially for heavy rust.

2. **Limited Effectiveness on Extremely Heavy Rust:** While effective on most rust, Evapo-Rust may struggle with extremely thick or layered rust deposits.

3. **Cost:** Evapo-Rust can be more expensive than some traditional rust removers, although the reusable formula helps offset the cost.

4. **Requires Submersion:** Evapo-Rust requires the rusted object to be fully submerged in the solution, which may not be practical for very large items.

**Ideal User Profile:**

Evapo-Rust is best suited for users who prioritize safety, ease of use, and preservation of metal integrity. It’s ideal for home mechanics, hobbyists, collectors, and anyone seeking a non-toxic and effective rust removal solution.

**Key Alternatives (Briefly):**

* **Phosphoric Acid-Based Rust Removers:** These are more aggressive than Evapo-Rust and can remove rust more quickly, but they are also more corrosive and require careful handling.

* **Abrasive Blasting:** This is a highly effective method for removing heavy rust, but it can also damage the underlying metal and requires specialized equipment.

**Expert Overall Verdict & Recommendation:**

Evapo-Rust is a highly recommended rust removal solution for its exceptional safety profile, ease of use, and effectiveness in removing rust without harming the underlying metal. While it may not be the fastest or most powerful option for extremely heavy rust, its benefits outweigh its limitations for most users. We confidently recommend Evapo-Rust for anyone seeking a safe, versatile, and effective way to *descaling rust*.

Insightful Q&A Section

Here are 10 insightful questions and expert answers regarding *descaling rust*:

1. **Q: How can I prevent flash rust from forming after descaling?**

**A:** Flash rust, a thin layer of rust that forms quickly after descaling, can be prevented by immediately applying a rust inhibitor, primer, or protective coating to the clean metal surface. Dehydrating the metal with heat or solvents can also help.

2. **Q: Can I use Evapo-Rust on painted surfaces?**

**A:** Evapo-Rust is generally safe on most paints, but it’s always best to test it on an inconspicuous area first. Prolonged exposure may soften or lift some paints.

3. **Q: What’s the best way to dispose of used Evapo-Rust?**

**A:** Used Evapo-Rust can be safely poured down the drain or disposed of in accordance with local regulations. It is biodegradable and non-toxic.

4. **Q: How long should I soak rusted items in Evapo-Rust?**

**A:** Soaking times vary depending on the severity of the rust. Light rust may be removed in a few hours, while heavy rust may require overnight soaking or longer.

5. **Q: Can I use a wire brush to speed up the descaling process with Evapo-Rust?**

**A:** While not necessary, gently scrubbing with a wire brush can help loosen stubborn rust and accelerate the descaling process.

6. **Q: What is the ideal temperature for using Evapo-Rust?**

**A:** Evapo-Rust works best at room temperature (around 70°F or 21°C). Colder temperatures may slow down the process.

7. **Q: How can I tell when Evapo-Rust is no longer effective?**

**A:** Evapo-Rust will become darker and less effective as it becomes saturated with rust particles. When it no longer removes rust effectively, it’s time to replace it.

8. **Q: Can I use Evapo-Rust on aluminum?**

**A:** While Evapo-Rust is primarily designed for iron and steel, it can be used on aluminum with caution. Test it on an inconspicuous area first, as prolonged exposure may discolor or etch the aluminum.

9. **Q: What safety precautions should I take when using rust removers?**

**A:** Even with non-toxic rust removers like Evapo-Rust, it’s always a good idea to wear gloves and eye protection to prevent skin and eye irritation.

10. **Q: How do I store metal objects after descaling to prevent future rust?**

**A:** After descaling, thoroughly dry the metal object and apply a rust inhibitor, primer, or protective coating. Store the object in a dry environment to prevent future rust formation.

Conclusion & Strategic Call to Action

In conclusion, *descaling rust* is a crucial process for maintaining the integrity, functionality, and value of metal objects. Understanding the causes of rust, exploring various removal methods, and implementing preventative measures are essential for effective rust management. Evapo-Rust stands out as a safe, versatile, and user-friendly solution for removing rust without harming the underlying metal. Its non-toxic formula, ease of use, and effectiveness make it an excellent choice for a wide range of applications.

As technology and materials science advance, we can anticipate even more innovative solutions for *descaling rust* in the future. The ongoing research and development in rust prevention and removal will continue to improve the longevity and performance of metal assets. We encourage you to share your experiences with descaling rust in the comments below and explore our advanced guide to rust prevention for more in-depth information. Contact our experts for a consultation on descaling rust and protecting your valuable metal investments.