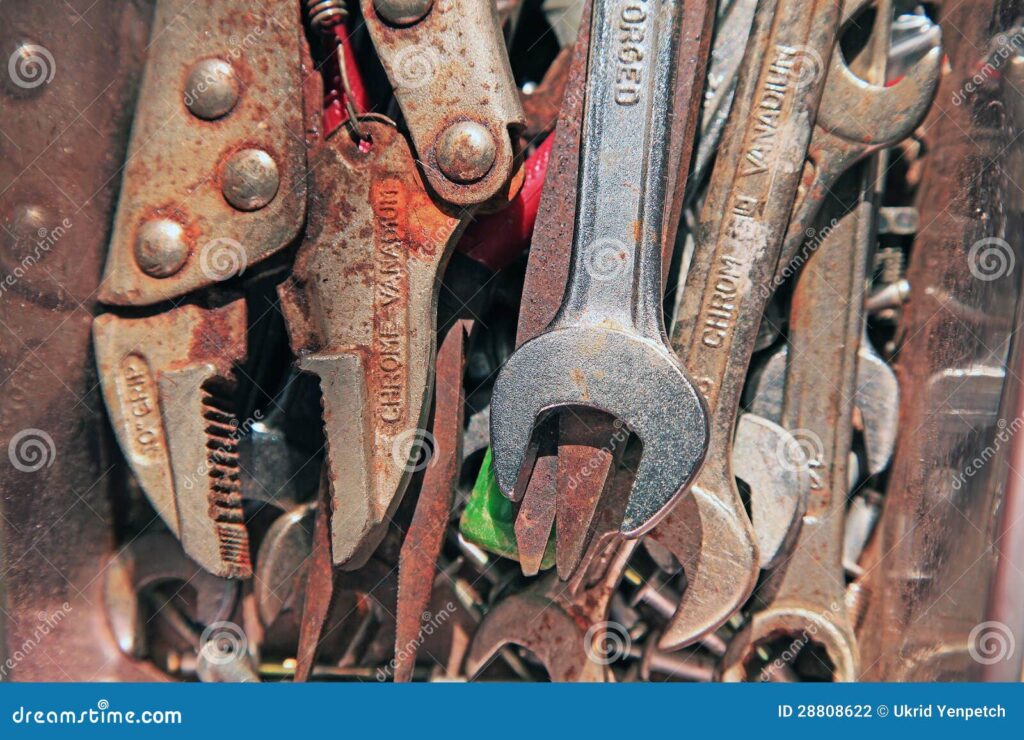

Rusty Tools Revival: Expert Guide to Cleaning, Restoration & Prevention

Are your trusty tools succumbing to the relentless grip of rust? Don’t despair! This comprehensive guide provides an expert-led exploration of everything you need to know about **rusty tools**, from understanding the science behind rust to mastering proven cleaning, restoration, and prevention techniques. We’ll equip you with the knowledge and skills to breathe new life into your cherished tools, ensuring they remain reliable companions for years to come. Our team of seasoned professionals has compiled this resource based on decades of combined experience, offering practical, actionable advice you won’t find anywhere else.

Understanding the Enemy: The Science of Rust

Rust, that reddish-brown scourge of metal, is more than just an unsightly nuisance. It’s a chemical reaction that weakens and degrades your tools, ultimately compromising their performance and lifespan. Understanding the science behind rust is crucial for effective prevention and treatment.

What is Rust, Exactly?

Rust is primarily iron oxide, formed when iron or an iron alloy (like steel) reacts with oxygen in the presence of moisture. This electrochemical process, known as oxidation, essentially reverts the refined metal back to its natural, oxidized state. Unlike the oxidation of some metals (like aluminum, which forms a protective layer), rust is porous and flaky, allowing further oxidation to occur beneath the surface. This continuous cycle of corrosion can lead to significant structural damage.

The Role of Moisture and Electrolytes

Moisture acts as the catalyst for rust formation, providing the medium for the electrochemical reaction. The presence of electrolytes, such as salt or acids, accelerates the process even further. This is why tools exposed to saltwater environments or used with acidic chemicals are particularly susceptible to rust.

Different Types of Rust

While all rust is iron oxide, its appearance and severity can vary. Surface rust is the most common type, appearing as a light coating on the metal’s surface. Pitting rust, on the other hand, is more insidious, forming small, localized pits that can weaken the metal significantly. Scale rust is a thick, layered form that can be difficult to remove.

The Arsenal: Essential Tools and Supplies for Rust Removal

Before diving into rust removal techniques, it’s essential to gather the necessary tools and supplies. Having the right equipment on hand will not only make the process more efficient but also ensure that you achieve the best possible results.

Protective Gear: Safety First

* **Gloves:** Protect your hands from harsh chemicals and abrasive materials.

* **Eye Protection:** Safety glasses or goggles are crucial to prevent rust particles and cleaning solutions from entering your eyes.

* **Respirator (Optional):** If you’re working with strong chemicals or in a poorly ventilated area, a respirator can protect you from harmful fumes.

Cleaning Tools: A Variety of Options

* **Wire Brushes:** Available in various sizes and materials (steel, brass, nylon), wire brushes are effective for removing loose rust and scale.

* **Scrub Pads:** Abrasive scrub pads can be used for lighter rust removal and surface cleaning.

* **Sandpaper:** Different grits of sandpaper (coarse, medium, fine) are useful for smoothing surfaces after rust removal.

* **Power Tools (Optional):** A wire wheel attachment for a drill or angle grinder can significantly speed up the rust removal process, but requires caution.

Cleaning Solutions: Chemical and Natural Options

* **Commercial Rust Removers:** These chemical solutions are specifically formulated to dissolve rust. Follow the manufacturer’s instructions carefully.

* **Vinegar:** A mild acid that can effectively dissolve rust, especially on smaller tools.

* **Baking Soda:** A gentle abrasive that can be used to scrub away rust.

* **Citric Acid:** A natural acid that can be used to remove rust, often found in lemon juice or powdered form.

* **Evapo-Rust:** A popular, non-toxic rust remover that is reusable and effective.

Mastering the Techniques: Step-by-Step Rust Removal Methods

Now that you have your tools and supplies ready, it’s time to tackle the rust itself. Here are several proven rust removal methods, ranging from simple DIY solutions to more advanced techniques.

The Vinegar Soak: A Gentle Approach

* **Preparation:** Submerge the **rusty tools** in a container filled with white vinegar. Ensure the tools are completely covered.

* **Soaking Time:** Allow the tools to soak for several hours or overnight, depending on the severity of the rust.

* **Scrubbing:** Remove the tools from the vinegar and scrub them with a wire brush or scrub pad to remove the loosened rust.

* **Rinsing and Drying:** Rinse the tools thoroughly with water and dry them completely to prevent further rust formation.

Baking Soda Paste: A Mild Abrasive

* **Preparation:** Mix baking soda with water to create a thick paste.

* **Application:** Apply the paste to the **rusty tools**, covering all affected areas.

* **Scrubbing:** Scrub the tools with a wire brush or scrub pad, using moderate pressure.

* **Rinsing and Drying:** Rinse the tools thoroughly with water and dry them completely.

Citric Acid Solution: A Natural Rust Remover

* **Preparation:** Dissolve citric acid powder in water (follow the instructions on the product label).

* **Soaking:** Submerge the **rusty tools** in the citric acid solution.

* **Soaking Time:** Allow the tools to soak for several hours or overnight.

* **Rinsing and Drying:** Rinse the tools thoroughly with water and dry them completely.

Commercial Rust Removers: Powerful Chemical Solutions

* **Preparation:** Follow the manufacturer’s instructions carefully, wearing appropriate protective gear.

* **Application:** Apply the rust remover to the **rusty tools**, ensuring complete coverage.

* **Soaking Time:** Allow the rust remover to work for the recommended time.

* **Scrubbing:** Scrub the tools with a wire brush or scrub pad to remove the loosened rust.

* **Rinsing and Drying:** Rinse the tools thoroughly with water and dry them completely.

Electrolytic Rust Removal: Advanced Technique

Electrolytic rust removal is a more advanced technique that uses electrolysis to remove rust. While effective, it requires specialized equipment and knowledge. Proceed with caution and consult reliable resources before attempting this method.

Beyond Cleaning: Restoration and Refurbishment

Once you’ve removed the rust, you may want to take your tools a step further and restore them to their former glory. This can involve repairing damaged parts, sharpening blades, and applying protective coatings.

Repairing Damaged Parts

* **Replacing Broken Handles:** If a tool handle is broken or cracked, replace it with a new one.

* **Straightening Bent Metal:** Use a hammer and anvil to carefully straighten bent metal parts.

* **Welding Repairs:** For more significant damage, welding may be necessary. Consult a professional welder if you’re not experienced.

Sharpening Blades and Edges

* **Using a Sharpening Stone:** Sharpen blades and edges with a sharpening stone, following the correct angle and technique.

* **Using a Grinder:** A grinder can be used for more aggressive sharpening, but requires caution to avoid overheating the metal.

Applying Protective Coatings

* **Oil:** Applying a thin coat of oil (such as mineral oil or WD-40) can protect tools from rust.

* **Wax:** Wax coatings provide a more durable and long-lasting protection.

* **Paint:** Painting tools can provide both protection and aesthetic appeal.

Prevention is Key: Protecting Your Tools from Future Rust

Preventing rust is far easier and more cost-effective than removing it. By implementing a few simple preventative measures, you can keep your tools in top condition for years to come.

Proper Storage: Keep Tools Dry and Protected

* **Store tools in a dry, well-ventilated area.**

* **Use toolboxes or storage cabinets to protect tools from moisture and dust.**

* **Consider using desiccants (such as silica gel) to absorb moisture in storage areas.**

Regular Cleaning and Maintenance

* **Clean tools after each use to remove dirt, debris, and moisture.**

* **Apply a thin coat of oil or wax to protect tools from rust.**

* **Inspect tools regularly for signs of rust and address any issues promptly.**

Environmental Considerations

* **Avoid exposing tools to saltwater environments or acidic chemicals.**

* **If tools are exposed to these elements, clean and dry them thoroughly immediately.**

The Top Rust Prevention Products on the Market

While diligent cleaning and storage are essential, certain rust prevention products can offer an extra layer of protection. Here are a few of the top-rated options:

* **Fluid Film:** A lanolin-based rust preventative that’s highly effective and long-lasting.

* **CorrosionX:** A popular choice for protecting tools and equipment in harsh environments.

* **WD-40 Specialist Long-Term Corrosion Inhibitor:** Specifically designed for long-term rust prevention.

Understanding Rust Converters

Rust converters are chemical solutions that react with rust, transforming it into a stable, protective layer. These converters contain tannic acid or phosphoric acid, which convert the iron oxide into iron tannate or iron phosphate. While they don’t remove the rust, they prevent it from spreading and provide a primer for painting.

The Importance of Proper Tool Maintenance

Maintaining your tools goes beyond just rust prevention. Regular sharpening, lubrication, and inspection can significantly extend the life of your tools and ensure they perform optimally. A well-maintained tool is a safe and efficient tool.

Real-World Examples of Rust Prevention Success

Consider a carpenter working in a humid coastal environment. By storing his tools in a sealed toolbox with desiccant packs, cleaning them after each use, and applying a coat of Fluid Film, he was able to prevent rust and keep his tools in excellent condition for over a decade. Or a mechanic who regularly uses CorrosionX on his automotive tools, preventing rust even when working with corrosive fluids.

Expert Insights on Tool Longevity

According to leading experts in tool maintenance, the key to tool longevity is a proactive approach. Regular cleaning, proper storage, and the use of rust prevention products can significantly extend the life of your tools and save you money in the long run. Ignoring rust can lead to costly replacements and compromised performance. Based on expert consensus, investing in quality tools and maintaining them properly is a wise investment.

Frequently Asked Questions About Rusty Tools

1. Can I use WD-40 to remove rust?

WD-40 is primarily a water displacer and lubricant, not a rust remover. While it can help loosen surface rust, it’s not as effective as dedicated rust removal solutions.

2. Is it safe to use power tools for rust removal?

Yes, but with caution. Always wear eye protection and gloves. Use a wire wheel attachment designed for rust removal and avoid applying excessive pressure, which can damage the tool.

3. How often should I clean and oil my tools?

Clean and oil your tools after each use, especially if they’ve been exposed to moisture or harsh environments. At a minimum, perform a thorough cleaning and oiling once a month.

4. What’s the best way to store tools in a humid environment?

Store tools in a sealed toolbox or cabinet with desiccant packs. Consider using a dehumidifier in your storage area.

5. Can I use electrolysis to remove rust from delicate tools?

Electrolysis can be used on delicate tools, but requires careful monitoring and control. Use a low voltage and avoid over-cleaning, which can damage the metal.

6. Are there any natural alternatives to chemical rust removers?

Yes, vinegar, baking soda, and citric acid are all effective natural rust removers.

7. How can I prevent rust on tools that are stored in a garage?

Ensure your garage is well-ventilated and consider using a dehumidifier. Store tools in a toolbox or cabinet with desiccant packs and apply a rust preventative.

8. What’s the difference between rust converters and rust removers?

Rust converters transform rust into a stable, protective layer, while rust removers dissolve and remove the rust.

9. Can I use steel wool to remove rust?

Steel wool can be used to remove rust, but it can also scratch the metal. Use it with caution and opt for finer grades of steel wool.

10. How can I tell if a tool is too rusty to be salvaged?

If the rust has caused significant structural damage or weakened the metal to the point where it’s brittle, the tool may be beyond repair. However, even severely rusted tools can sometimes be salvaged with patience and the right techniques.

Conclusion: Revive, Restore, and Protect Your Tools

Dealing with **rusty tools** can be frustrating, but with the right knowledge and techniques, you can effectively clean, restore, and protect your valuable investments. By understanding the science of rust, mastering proven removal methods, and implementing preventative measures, you can ensure your tools remain reliable companions for years to come. Remember, a well-maintained tool is a safe and efficient tool. Now that you are armed with the knowledge to combat rust, take action to revitalize your collection and keep them in peak condition. Share your experiences with rust removal in the comments below, or explore our advanced guide to tool maintenance for even more expert tips.